Lithologic Photo

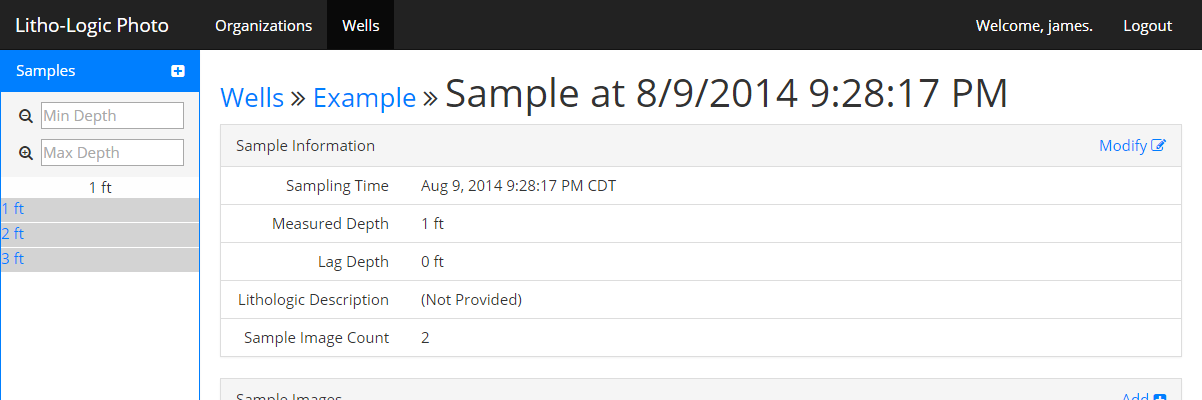

Lithologic Photo was a big project intended to create a database of rock sample photography, extracting quantifiable information for other uses. I worked on the front-end of this project while a second programmer specifically handled the back-end.

The front-end was a monolithic single-page application built in CoffeeScript and Ember, supported by various other technologies such as Stylus, Emblem, and Twitter's Bootstrap. The back-end was built on Amazon's Web Services. The project was pretty mature at the time it was shelved.

Purpose & Use

The idea with Lithologic Photo was to provide a simple means for mud-loggers to catalog photography of a well's rock samples in as close to real-time as possible and make it dead simple for decision makers to get access to that information.

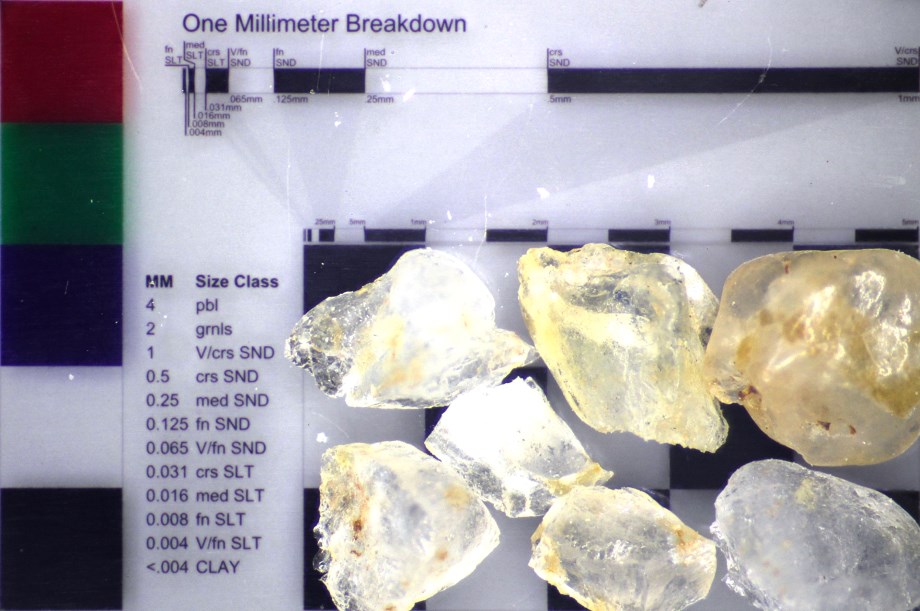

To put it more simply, it was an image database system specializing in tiny, ground-up rocks.

The photography was to be done using a special photography plate; simple image detection was used to pin-point color swatches on the plate to use as guides in the color correction. Combined with Lithologic, a standardized, high-quality description of the rock would also be provided.

The hope was this information would be quantitative enough to act as additional data to improve geosteering, and this project would naturally have lead into TerraVu 3.

Design & Development

At the time the project was getting off the ground, Microsoft was showing off their "Metro" design language, later renamed to the way lamer "MDL". Since I found its simplistic design with hard corners and bold colors rather appealing and easy to work with, I adopted it for this project.

In all honesty, the programming was the easy part. The API provided by my back-end developer just worked and flowed beautifully into the front-end. It all worked exactly as I needed it and Ember interacted with it swimmingly. Aside from a few performance problems concerning rendering lists of thousands of samples, it was all smooth on the programming front.

No, the hard part was all the stuff that wasn't programming.

As I said before, the software relied on the photography being done on special plates. These plates needed to be designed and manufactured, so I had to break out a copy of Autodesk Inventor and produce a CAD drawing which could be 3D printed for testing and later used in mass-production.

Along with that, I also had to produce the graphic with the color swatches to affix to the plate and make it microscope-sized. This required the services of, so far as we know, the only color micro-film printing company that exists in the world.

Finding them was hard; coordinating with them across the world was harder; not losing the microfilm we put considerable effort into purchasing turned out to be impossible.

It was not me that lost it though, just to be clear. Someone else was handling the actual manufacture of the plates and they had a hard time keeping track of that tiny black box worth $1000 ...or the other one we got when we ordered prints of the version 2 graphic.

This, and other problems like it, eventually took their toll on the project.